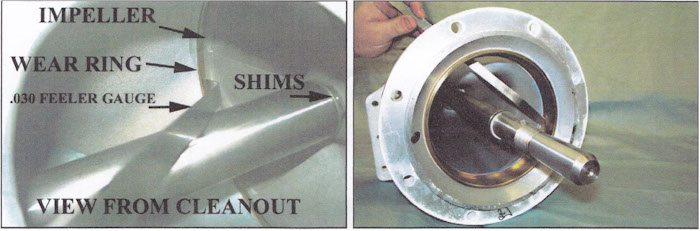

IMPELLER / WEAR RINGS SHIMMING INSTRUCTIONS

Tools Needed:

1. 0.30 feeler gauge

2. Propane torch.

3. Bent screwdriver

4. WD-40

5. Impeller wrench

6. 3/4" wrench

7. 9/16" wrench

8. Dead blow hammer

Use a propane torch. Place the flame on the brass ring go around in a circular motion until the insulator starts to melt. Grab the ring with a bent over screwdriver (90 degrees) and pull out. Clean up wear ring bore.

Installation:

Place wear ring in freezer for four hours. Place insulator in suction bore. Spray with WD-40. Start wear ring by hand. Tap wear ring in using a wooden block and a mallet. You may use an old impeller, but it may bottom out on the shaft before seating the ring.

Important:

Wear ring must be seated square in the bore within 0.004" side to side.

The axial clearance between the impeller and the impeller shoulder must be 0.025"-0.035" (check several places around the wear ring.) Check again after the impeller nut has been tightened.

Torque impeller nut to 70 ft/lbs. Torque bowl bolts to 50 ft/lbs.